| ALUMINUM PUMP SEAL KIT Part # 9668 Seal and spring kit Part # 9065 Seal and spring kit with S.S. piston |

Instruction Sheet |

The Kit Includes:

Part # 9668 Seal and spring kit

Part # 9065 Seal and spring kit with S.S. piston

Is Your Accu-Lube Pump Compatible?

|

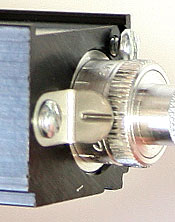

NOTE: The pump repair kit is only compatible with Accu-Lube pumps identified by a ratchet clip (#11) on the back side of the aluminum knurled oil adjustment stem. Pumps built prior to this are not serviceable. The lubricant adjustment knob (#10) is calibrated specific to the individual pump body. Ensure that the lubricant knob is assembled to the original pump body. |

Illustration

# REQ KIT DESCRIPTION 1 1 1 O RING .750 I.D. X .062, VITON 2 1 1 U-CUP 1/2 I.D. X 1/16 VITON 3 1 1 RETURN SPRING 4 2 3 O RING .301 I.D. X .070, VITON 5 1 1 O RING .065 I.D. X .035, VITON 6 1 1 EVAC VALVE 7 1 1 CONICAL EVAC SPRING 8 1 2 O RING .114 I.D. X .070, VITON 9 1 1 O RING .426 I.D. X .070, VITON 10 1 LIQUID ADJUSTMENT STEM 11 1 RATCHET CLIP 12 2 6/32 PAN SCREW 13 1 PUMP BODY 14 1 O RING RETAINING RING 15 1 1/8" PISTON 16 1 OIL LINE SLEEVE 17 1 HOSE BARB OUTLET 18 1 AIR ADJUSTMENT STEM 19 1 ADAPTOR 20 1 E-CLIP

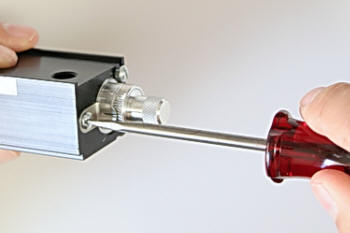

1. Remove

items 18/19 (air adjustment stem) to replace item 4 (o ring) / set aside.

2. Remove

item 17 (hose barb) and replace item 4 (o ring) / set aside.

3. Remove

items 11 and 12 (ratchet clip and small screws) / set aside.

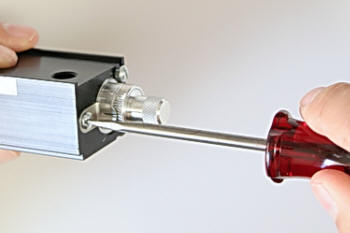

4. Unscrew

item 10 (knurled aluminum oil adjustment knob)

IMPORTANT NOTE: ITEM 10 IS

CALIBRATED TO THE SPECIFIC PUMP BODY KEEP TOGETHER WITH BODY!

NOTE; REMOVE ITEM 10 SLOWLY

TO PREVENT ITEM 15

(PISTON) FROM BEING DAMAGED.

ITEM 3 (RETURN SPRING) WILL

EJECT ITEM 15 UPON REMOVAL OF ITEM

10.

NOTE; ITEM 15 IS A PRECISION PART HANDLE WITH CARE

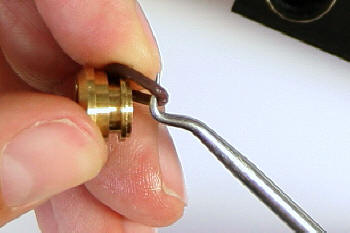

5. Replace items 2 (u-cup) and 5 (O ring) on item 15 (piston) set aside

6. Replace

item 1 (large o-ring) on item 10 / set aside

6a. Replace item 4 behind item 14 "difficult"

(click to see

detail instructions).

7. Using

a 3/32 O.D. stem tool, insert into large diameter hole, through piston hole,

forcing out items 6 (evac valve), 7 (evac spring), and 14 (o ring).

8. Replace

item 4 (o ring) on item 16 (oil line sleeve).

9. Re-insert

new items 6 & 7 (evac valve and spring)

10. Insert

item 16, NOTE; press fit with a tool, until snug and stays in.

11. Insert

new item 8 (o ring) into recess of item 16 (oil line sleeve).

12. Re-install

item 17 (only until finger snug).

13. Re-install

item 18/19. Tighten with a 9/16” wrench.

14. At

opposite end, re-install item 15 with new item 3 (return spring).

15. Re-install

item 10 (oil adjustment stem) to stop.

NOTE; DO

NOT CROSS THESE VERY FINE THREADS!

16.

Re-install items 11 (ratchet clip) and 12 (small screws).

You are

done

|

|